18 Oborn Road Mount Barker

"Adelaide Hills Straco Outback® Dealer - Mt Barker Steel"

"Adelaide Hills Straco Outback® Dealer - Mt Barker Steel"

Mt Barker Home Improvements Centre is proud to be the Adelaide Hills Stratco Outback® Dealer. Since 1996, we have worked with Stratco to supply and installed Outback™ Carports, Verandahs and Pergolas to hundreds of Adelaide Hills’ homes. In the early days Mt Barker Home Improvements Centre mainly installed Stratco Flat roof Verandahs, but now we can supply and install the full range of Outback® styles ensuring there is a Carport, Verandah and Pergola to fit every house. You can choose from Traditional or Dutch gable, Hip or Gazebo ends, Curved roofed and even the new Pavillion. With so much choice we can help you choose a design to suit your taste and budget!

Mt Barker Home Improvements Centre is proud to be the Adelaide Hills Stratco Outback® Dealer. Since 1996, we have worked with Stratco to supply and installed Outback™ Carports, Verandahs and Pergolas to hundreds of Adelaide Hills’ homes. In the early days Mt Barker Home Improvements Centre mainly installed Stratco Flat roof Verandahs, but now we can supply and install the full range of Outback® styles ensuring there is a Carport, Verandah and Pergola to fit every house. You can choose from Traditional or Dutch gable, Hip or Gazebo ends, Curved roofed and even the new Pavillion. With so much choice we can help you choose a design to suit your taste and budget!

For a no obligation quote please call the Adelaide Hills Stratco Outback Dealer representatives David or Craig on (08) 8391 0499 or you can email us via our contact us page.

Stratco Outback Flat Roof

Create an attractive and functional outdoor living area that will enhance your home and lifestyle with the smooth, simple, uncluttered lines of the classic Stratco Outback Flat Roof.

This versatile Flat Roofing system can be configured to cover any area around the home.

Adapt the versatile Stratco Outback Flat Roof to suit your lifestyle

The Stratco Outback Flat Roof system is extremely versatile and can be configured to cover any area around the home.

It is ideal as a single unit or can be incorporated with a gable roof, curved roof, or pergola system for extra cover.

Available as a freestanding structure or attached to the home, it can be used as a carport, verandah or patio.

With the addition of Outback Rooflite, you can supply filtered light to the underside.

The beams can span up to 8.4 metres and are available in either 120mm or 150mm sizes.

Four configurations – Giving you choice and control

There are four Stratco Outback Flat Roof configurations to choose from:

- Type 1 Has a 4.5 metre maximum span and only requires an outside beam to support the structure. However most units use perimeter beams on all sides to provide the best appearance.

- Type 2 Is the same as Type 1, but also has an overhang at the front to increase the covered area to 5.4 metres.

- Type 3 Has support beams across its span so roofing sheets can run horizontally for a different appearance.

- Type 4 Has extra support beams and a purlin through the middle to give a span of 8.4 metres.

Technical Details

Maximum Spans

| Flat Outback Attached – Maximum Spans (mm) | ||||||

| Wind Speed | Type 1A 120 or 150 Beam | Type 2A 120 or 150 Beam | Type 3A | Type 4A | ||

| 120 Beam | 150 Beam | 120 Beam | 150 Beam | |||

| N1 (W28) | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| N2 (W33) | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| W36N | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| N3, C1 (W41) | 4500* | 4500* | 7200 | 8400 | 6000 | 8400 |

| N4, C2 (W50) | 4500* | 4500* | 6000* | 8400 | 6000 | 8400* |

| W55C | 2700 | 3000 | 5400 | 7800 | 6000 | 6600 |

| C3 (W60) | 2700† | 2700 | 4800 | 4800 | 5400 | 6600 |

* Applies to non-cyclonic designs only.

† Height limited to 2400mm.

| Flat Outback Freestanding – Maximum Span (mm) | ||||||

| Wind Speed | Type 1F 120 or 150 Beam | Type 2F 120 or 150 Beam | Type 3F | Type 4F | ||

| 120 Beam | 150 Beam | 120 Beam | 150 Beam | |||

| N1 (W28) | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| N2 (W33) | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| W36N | 4500 | 4500 | 7200 | 8400 | 6000 | 8400 |

| N3, C1 (W41) | 4500* | 4500* | 7200* | 8400 | 6000 | 8400* |

| N4, C2 (W50) | 4500* | 4500* | 6000* | 7200* | 6000 | 7200* |

| W55C | 3300 | 3300 | 4800 | 6000 | 5400 | 6000 |

| C3 (W60) | 3000 | 3000 | 4200 | 5400 | 5100 | 6000 |

* Applies to non-cyclonic designs only.

Connection Details

Flat Attached

Flat Freestanding

Components

| 1. Outback Deck | 7. Downpipe Strap | 13. Notched Beam Filler |

| 2. Beams | 8. Downpipe Outlet | 14. Beam to Beam Bracket |

| 3. Gutter | 9. Gutter Mitre | 15. Post Bracket |

| 4. Back Channel & BIP Foam | 10. Gutter Stop End | 16. Post Cap |

| 5. Columns | 11. Wall Bracket | 17. Freestanding Column Bracket |

| 6. Downpipe | 12. Beam End Bracket |

Fixing Details

For Non-Cyclonic Areas

Two 12 x 20mm self drilling screws per pan at each support and two 3.2mm sealed aluminium rivets per pan at the back channel. If decking runs parallel to the back channel, secure to channel with rivets at maximum 200mm centres. All screws require neoprene washers.

For Cyclonic Areas

Three 12 x 20mm self drilling screws per pan at each support. For deck spans less than 3600mm, two self drilling screws per pan are to be used on the fascia beam. Three 4.8mm sealed aluminium rivets per pan (or 150mm centres if sheets are parallel) are to be used on the back channel. All screws require neoprene washers.

Roof Sheeting

Outback Deck

Outback Rooflite – Polycarbonate

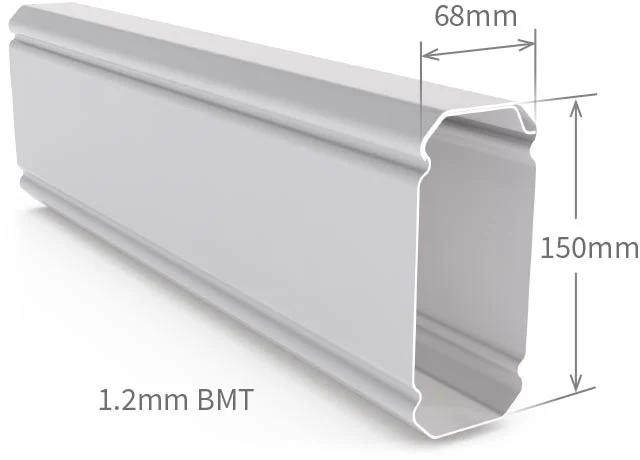

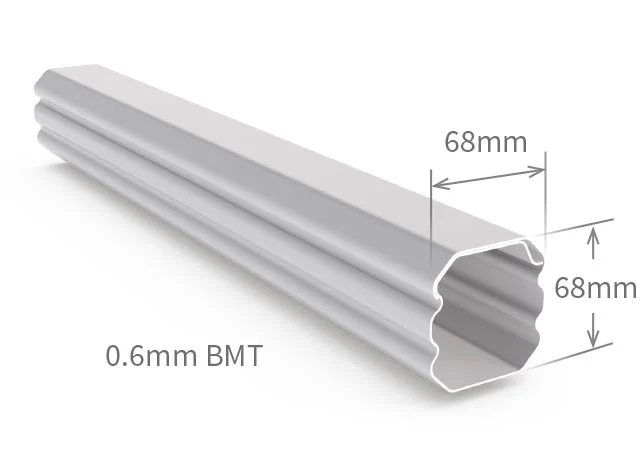

Structural Sections

|  |

| 120mm Beam | 150mm Beam |

|  |

| Post | Purlin | Back Channel |

Design Considerations

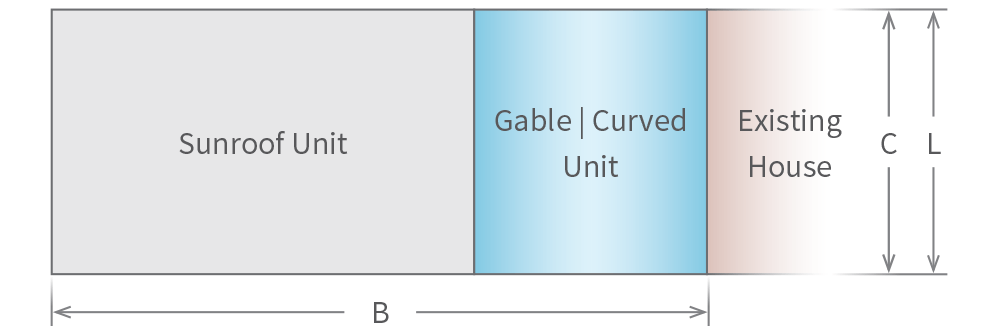

Gable or curved units attached between a flat unit and an existing structure

Gable or curved units which are attached between a flat unit (excluding pergolas) and an existing house, are only be considered attached if the gable or curved unit is attached to the existing house (C) for its full length (L) and the longest side of the combined unit (B) does not exceed twice the gable or curved unit length (L). The flat unit in this case can be considered attached. This style requires all coloumns to be embedded into footings.

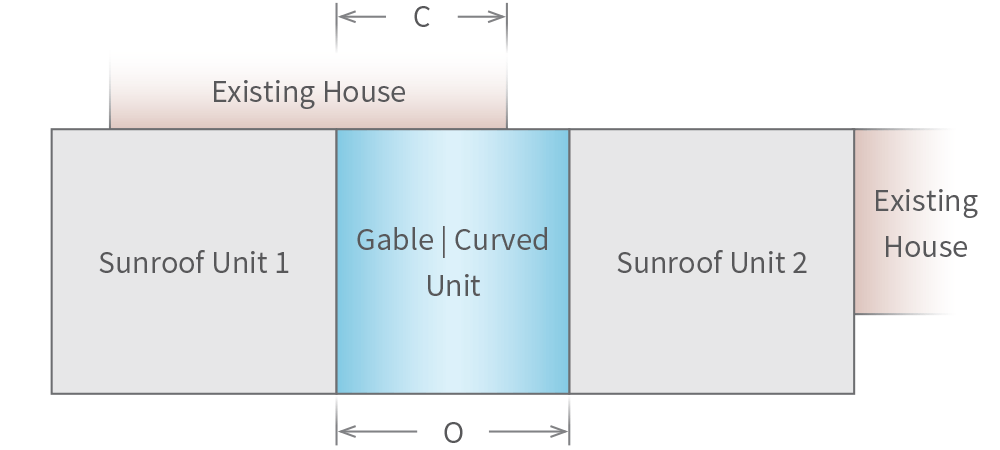

Gable or curved units attached to a flat unit on one or both sides

Gable or curved units which are attached on one or both sides to flat units, (excluding pergolas) must be attached to a house for at least 75% of the gable or curved opening length (O) to be considered attached. Flat units must be deemed attached as detailed in the flat unit section below to allow the gable or curved unit to be considered attached.

Gable or curved units are considered attached on both sides if both the flat 1 and 2 comply with the attachment rules for flat units as detailed below. Gable or curved units are considered attached on one side if only one flat unit exists and it complies with the attachment rules for flat units as detailed below.

Flat units

A verandah, patio or carport is deemed to be freestanding unless it is attached to an existing house (C) for at least 75% of the length of its shortest side (A), and its longest side (B) does not exceed twice the length of its shortest side.

Design Options

When designing an Outback Patio, consideration should be given to both the roof sheet direction, and the orientation of any openings and overhangs involved. These are often determined by appearence and drainage requirements. Some of the normal configurations are shown below. Contact Stratco if assistance is required.

Stratco Outback Gable Roof

Exhibiting a strong presence and style, the pitched roof of a Stratco Outback Gable Carport, Pergola, Veranda or Patio is endowed with an open feel that will enrich your home and outdoor area.

Exhibiting a strong presence and style, the pitched roof of a Stratco Outback Gable Carport, Pergola, Veranda or Patio is endowed with an open feel that will enrich your home and outdoor area.

Enhance your lifestyle with a Stratco Outback Gable veranda, patio or carport

The Stratco Outback Gable is available as a freestanding unit or attached to your home. Combined with flat roof or pergola sections, the prominent pitched roof becomes the main feature of the design.

The gable is available in our Multispan or Clearspan design. Match the Outback Deck with Outback Rooflites to supply natural filtered light.

Multispan Gable

The Outback Multispan Gable offers a range of roof cladding materials. It features purlins that are placed over the rafters in the roof. This supports the cladding, which can be the smooth Outback Deck, light and airy polycarbonate, or classic corrugated steel.

The gable can span up to 6.6 metres wide when attached at both ends, or 3 metres wide when attached at one end.

Clearspan Gable

The Outback Clearspan Gable uses only the Outback Deck, a very strong material that does not need extra purlins to support it. This leaves the roof area clean and uncluttered.

The Clearspan Gable can span an impressive 7.5 metres wide with a 22 degree pitch.

Technical Details

Maximum Spans

| Outback Multispan Gable – Maximum Opening (O) in mm | ||||||||

| Wind Speed | Attached to the wall or fascia on one side only. | Attached on one side and to the wall or fascia on one end. Using 120 or 150 valley beams. | Attached to a flat unit on one side and a wall or fascia on the opposite side. Or attached both sides and to the wall or fascia one end. Using 120 or 150 valley beams. | |||||

| 120 or 150 Valley Beams | Type 1A or 2A | Type 3A | Type 4A | Type 1A | Type 2A | Type 3A | Type 4A | |

| N1 (W28) | 6600* | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 |

| N2 (W33) | 6600* | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 |

| W36N | 6300* | 6300 | 6000 | 6000 | 6600 | 6600 | 6600 | 6600 |

| N3 (W41) | 5700* | 5700 | 3000 | 4800 | 6600 | 6600 | 3000 | 6600 |

| C1 (W41) | 5400* | 5700 | 3000 | 4800 | 5700 | 5700 | 3000 | 5700 |

| N4 (W50) | 4200* | 3000 | – | 3300 | 3000 | 4800 | – | 4800 |

| C2 (W50) | 4200* | 3000 | – | 3300 | 3000 | 3900 | – | 3900 |

| W55C | 3600* | 2400 | – | 2400 | – | 3000 | – | 3000 |

| C3 (W60) | 3000* | 2100† | – | 2100 | – | 3000 | – | 3000 |

* Minimum of four columns along the length of the gable unit on the opposite side of the attachment when solid infill is used.

† Height limited to 2400mm for flat unit type 1A.

| Outback Clearspan Gable – Maximum Opening (O) in mm | ||||||||

| Wind Speed | Attached to the wall or fascia on one side only. | Attached on one side and to the wall or fascia on one end. Using 120 or 150 valley beams. | Attached to a flat unit on one side and a wall or fascia on the opposite side. Or attached both sides and to the wall or fascia one end. Using 120 or 150 valley beams. | |||||

| 120 or 150 Valley Beams | Type 1A or 2A | Type 3A | Type 4A | Type 1A | Type 2A | Type 3A | Type 4A | |

| N1 (W28) | 6600* | 6600 | 6600 | 6600 | 7500 | 7500 | 7500 | 7500 |

| N2 (W33) | 6600* | 6600 | 6600 | 6600 | 7500 | 7500 | 7500 | 7500 |

| W36N | 6300* | 6300 | 6300 | 6300 | 7500 | 7500 | 7500 | 7500 |

| N3 (W41) | 5700* | 5700 | 3600 | 5100 | 7500 | 7500 | 6300 | 7500 |

| C1 (W41) | 5400* | 5700 | 2700 | 4800 | 5700 | 5700 | 2700 | 4800 |

| N4 (W50) | 4200* | 4500 | 2700 | 4500 | 4800 | 4800 | 2700 | 4800 |

| C2 (W50) | 4200* | 4500 | 2700 | 4500 | 4800 | 4800 | 2700 | 4800 |

| W55C | 3600* | 3900 | 2100 | 3900 | 4200 | 4500 | 2100 | 4500 |

| C3 (W60) | 3000* | 2700† | – | 2700 | 2700† | 3600 | – | 3300 |

* Minimum of four columns along the length of the gable unit on the opposite side of the attachment when a solid infill is used.

† Height limited to 2400mm.

N = Non-cyclonic wind classification.

C = Cyclonic wind classification.

Connection Details

Clearspan

Multispan

Components

| 1. Ridge Cap | 9. Gable Beam Bracket | 17. End Strut |

| 2. Outback Deck | 10. Header Beam | 18. End Strut Plate |

| 3. Ridge Beam | 11. Barge Cap | 19. Multispan Gable Roofing |

| 4. Ridge Knuckle | 12. Post Bracket | 20. Purlin |

| 5. Gable Rafter | 13. Post | 21. End Rafter Bracket |

| 6. Valley Beam | 14. Front Fascia Beam | 22. Post Cap |

| 7. Angled Back Channel | 15. Gutter | |

| 8. Beam Capping | 16. Header Beam Bracket |

Fixing Details

For Non-Cyclonic Areas

Two 12 x 20mm self drilling screws per pan at each support and two 3.2mm sealed aluminium rivets per pan at the back channel. If decking runs parallel to the back channel, secure to channel with rivets at maximum 200mm centres. All screws require neoprene washers.

For Cyclonic Areas

Three 12 x 20mm self drilling screws per pan at each support. For deck spans less than 3600mm, two self drilling screws per pan are to be used on the fascia beam. Three 4.8mm sealed aluminium rivets per pan (or 150mm centres if sheets are parallel) are to be used on the back channel. All screws require neoprene washers.

Roof Sheeting

Outback Deck

Outback Rooflite – Polycarbonate

Structural Sections

|  |

| 120mm Beam | 150mm Beam |

|  |

| Post | Purlin | Back Channel |

Design Considerations

Gable units attached between a flat or Sunroof unit and an existing structure

Gable units which are attached between a flat or Sunroof unit (excluding pergolas) and an existing house, are only considered attached if the gable unit is attached to the existing house (C) for its full length (L) and the longest side of the combined unit (B) does not exceed twice the gable unit length (L). The flat or Sunroof unit in this case can be considered attached. This style requires all coloumns to be embedded into footings.

Gable units attached to a flat or Sunroof unit on one or both sides

Gable units which are attached on one or both sides to flat or Sunroof units, (excluding pergolas) must be attached to a house for at least 75% of the gable opening length (O) to be considered attached. Flat or Sunroof units must be deemed attached as detailed in the flat or Sunroof unit section below to allow the gable unit to be considered attached.

Gable units are considered attached on both sides if both the flat 1 and 2 comply with the attachment rules for flat or Sunroof units as detailed below. Gable units are considered attached on one side if only one flat or Sunroof unit exists and it complies with the attachment rules for flat or Sunroof units as detailed below.

Design Options

When designing an Outback Patio, consideration should be given to both the roof sheet direction, and the orientation of any openings and overhangs involved. These are often determined by appearence and drainage requirements. Some of the normal configurations are shown below. Contact Stratco if assistance is required.

Note: When attaching gable patios to Sunroof units, please refer to ‘The Rules of Attachment to Standard Outback Systems’ in the ‘Outback Sunroof Span Tables Book’.

Stratco Outback Curved Roof

The contemporary form of the Stratco Outback Curved Roof Carport, Verandah or Patio will add value and impart a sense of style and sophistication to your home.

The contemporary form of the Stratco Outback Curved Roof Carport, Verandah or Patio will add value and impart a sense of style and sophistication to your home.

The smooth, clean lines of the curved roofing form a graceful canopy over any outdoor area.

Create a contemporary verandah or patio with the Stratco Outback Curved Roof

The Stratco Outback Curved Roof is available as a freestanding unit or attached to your home.

When combined with flat roofing or pergola sections it becomes part of a system, with the elegant curved roof forming the central feature of the design.

Available in either Multispan or Clearspan designs, the Stratco Outback Curved Roof can span up to 6.6 metres wide in either style.

Multispan Curved Roof

The Outback Multispan Curved Roof has purlins that are placed over the rafters in the roof.

These purlins support your choice of cladding:

- Smooth Outback Deck

- Light and airy polycarbonate

- Classic corrugated steel

The corrugated steel is supplied pre-curved to the required radius for easy installation.

Clearspan Curved Roof

The Outback Clearspan Curved Roof minimises beams and rafters by using Outback Deck.

Outback Deck is a very strong material that does not need extra purlins to support it. This leaves the roof area clean and uncluttered with a ceiling-like appearance from beneath.

Outback Rooflites are also available to supply natural filtered light when Outback Deck is used in Clearspan designs.

Technical Details

Maximum Spans

| Outback Multispan and Clearspan Curve – Maximum Opening (O) in mm | ||||||||

| Wind Speed | Rear attached to a wall or fascia (full length). | Attached a to wall or fascia on one side only. | Attached on one side and to the wall or fascia on one end. | Attached to a flat unit on one side and a wall or fascia on the opposite side. Or attached both sides and to the wall or fascia on one end. | ||||

| 120 or 150 Valley Beams | 120 or 150 Valley Beams | |||||||

| 120 or 150 Valley Beams | 120 or 150 Valley Beams | Type 1A or 2A | Type 3A | Type 4A | Type 1A or 2A | Type 3A | Type 4A | |

| N1 (W28) | 4500 | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 |

| N2 (W33) | 4500 | 6600* | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 |

| W36N | 4500 | 6300* | 6600 | 6600 | 6600 | 6600 | 6600 | 6600 |

| N3 (W41) | 4500 | 5700* | 6600 | 5700 | 5400 | 6600 | 5700 | 5400 |

| C1 (W41) | 4500 | 5700* | 6600 | 5700 | 5400 | 6600 | 5700 | 5400 |

| N4 (W50) | 4500 | 4200* | 4500 | 4500 | 4800 | 4800 | 4500 | 4800 |

| C2 (W50) | 4500 | 4200* | 4500 | 4500 | 4800 | 4800 | 4500 | 4800 |

| W55C | 3600 | 3600* | 4200 | 3600 | 3000 | 4200 | 3600 | 4200 |

| C3 (W60) | 3600 | 3300* | 3600 | 3000 | 3000 | 3600 | 3000 | 3300 |

* Minimum of four columns along the length of the gable unit on the opposite side of the attachment when solid infill is used.

N = Non-cyclonic wind classification.

C = Cyclonic wind classification.

Connection Details

Components

| 1. Multispan Curved Roofing | 6. Curve to Valley Bracket | 11. Side Fascia Beam |

| 2. Outback Deck | 7. Curved Barge Cap | 12. Post Bracket |

| 3. Purlin | 8. Notched Beam Filler | 13. Beam End Cap |

| 4. Rafter | 9. Beam to Beam Bracket | 14. Post |

| 5. Valley Beam | 10. Front Fascia Beam | 15. Gutter and Gutter Stop End |

Fixing Details

For Non-Cyclonic Areas

Two 12 x 20mm self drilling screws per pan at each support and two 3.2mm sealed aluminium rivets per pan at the back channel. If decking runs parallel to the back channel, secure to channel with rivets at maximum 200mm centres. All screws require neoprene washers.

For Cyclonic Areas

Three 12 x 20mm self drilling screws per pan at each support. For deck spans less than 3600mm, two self drilling screws per pan are to be used on the fascia beam. Three 4.8mm sealed aluminium rivets per pan (or 150mm centres if sheets are parallel) are to be used on the back channel. All screws require neoprene washers.

Roof Sheeting

Outback Deck

Outback Rooflite – Polycarbonate

Structural Sections

|  |

| 120mm Beam | 150mm Beam |

|  |

| Post | Purlin | Back Channel |

Design Considerations

Curved units attached between a flat or Sunroof unit and an existing structure

Curved units which are attached between a flat or Sunroof unit (excluding pergolas) and an existing house, are only considered attached if the curved unit is attached to the existing house (C) for its full length (L) and the longest side of the combined unit (B) does not exceed twice the curved unit length (L). The flat or Sunroof unit in this case can be considered attached. This style requires all coloumns to be embedded into footings.

Curved units attached to a flat or Sunroof unit on one or both sides

Curved units which are attached on one or both sides to flat or Sunroof units, (excluding pergolas) must be attached to a house for at least 75% of the curved opening length (O) to be considered attached. Flat or Sunroof units must be deemed attached as detailed in the flat or Sunroof unit section below for the curved unit to be considered attached.

Curved units are considered attached on both sides if both the flat 1 and 2 comply with the attachment rules for flat or Sunroof units as detailed below. Curved units are considered attached on one side if only one flat or Sunroof unit exists and it complies with the attachment rules for flat or Sunroof units as detailed below.

Design Options

When designing an Outback Patio, consideration should be given to both the roof sheet direction, and the orientation of any openings and overhangs involved. These are often determined by appearence and drainage requirements. Some of the normal configurations are shown below. Contact Stratco if assistance is required.

Note: When attaching curved patios to Sunroof units, please refer to ‘The Rules of Attachment to Standard Outback Systems’ in the ‘Outback Sunroof Span Tables Book’.

Stratco Outback Gazebo & Hip End

Complete the open end of your Stratco Outback Gable with a Hip End or Gazebo.

Designed to add a new dimension to your verandah, pergola or patio and complement the existing architecture of your home.

Add a new dimension to your verandah or patio with an Outback Gazebo or Hip End

Stratco Outback Hip End

With its enduring style, the Stratco Outback Hip End will add a traditional charisma to your home.

With its enduring style, the Stratco Outback Hip End will add a traditional charisma to your home.

The Hip End is an elegant addition that completes the end of a Stratco Outback Gable.

Designed to complement the existing architecture of homes with a hip end in the roofline. The Hip End can be used to great effect on one or both ends of a gable.

Stratco Outback Gazebo End

Exuding charm and character, the Stratco Outback Gazebo End adds a new dimension to the end of a Stratco Outback Gable.

Exuding charm and character, the Stratco Outback Gazebo End adds a new dimension to the end of a Stratco Outback Gable.

Designed to provide the finishing touch, its distinctive form will impart a refined and elegant air to your home.

The Gazebo End has been designed to enhance the appeal of any home, and works especially well on homes with bay windows and hexagon forms in the roof design.

Hip End

Hip End Section Details

Connection Details

Clearspan

Multispan

Components

| 1. Ridge Cap | 9. Beam to Beam Braket | 17. Purlin |

| 2. Ridge Knuckle | 10. Notched Beam Filler | 18. Purlin Intersection Cover |

| 3. Hip Rafter | 11. Perimeter Bracket | 19. 90° Angled Purlin Connector |

| 4. Hip Fascia Beam | 12. Outback Deck | 20. Front Fascia Beam |

| 5. Hip Apex Bracket | 13. 2 Piece Clearspan Back Channel | 21. Centre Hip Rafter |

| 6. Rafter to Valley Bracket | 14. Beam Capping | 22. Hip Support Flashing |

| 7. Post Bracket | 15. Hip End Beam Capping Mitre | |

| 8. Post | 16. Polycarb, Outback Deck or CGI |

Gazebo End

Gazebo End Section Details

Connection Details

Clearspan

Multispan

Components

| 1. Ridge Cap | 8. Post | 15. Gazebo Beam Capping Mitre |

| 2. Ridge Knuckle | 9. Post Cap | 16. Polycarb, Outback Deck or CGI |

| 3. Hip Rafter | 10. Outback Deck | 17. Purlin |

| 4. Gazebo Fascia Beam | 11. 2 Piece Clearspan Back Channel | 18. Purlin Intersection Cover |

| 5. Gazebo Apex Bracket | 12. Beam Capping | 19. 135° Angled Purlin Connector |

| 6. Rafter to Valley Bracket | 13. 67.5° Angled Inline Beam Connector | 20. Hip Support Flashing |

| 7. Post Bracket | 14. Perimeter Bracket |

Stratco Outback Heritage

Complete the open end of your Stratco Outback Gable with a Hip End or Gazebo.

Designed to add a new dimension to your verandah, pergola or patio and complement the existing architecture of your home.

The Stratco Outback Heritage Gable will imbue your home with a traditional style

The Stratco Outback Heritage is available as either:

- Traditional Gable

- Dutch Gable

Both Outback Heritage Gable styles are available attached or freestanding, and use corrugated iron or polycarbonate as their cladding. The standard eave height is 2.4 metres, but can be ordered up to 3 metres high.

Traditional Gable

With a classic pitched roof, and impressive widths of up to 8.4 metres, the Traditional Heritage Gable is extremely versatile. It is available with a roof pitch of either 22 or 30 degrees, and a range of optional gable end infills.

With a classic pitched roof, and impressive widths of up to 8.4 metres, the Traditional Heritage Gable is extremely versatile. It is available with a roof pitch of either 22 or 30 degrees, and a range of optional gable end infills.

Dutch Gable

The distinctive Dutch Heritage Gable style embodies a classic personality thatcomplements traditional homes. Available in widths of up to 7.5 metres, and a roof pitch of 22 degrees, it comes with a fibre-cement sheet infill in the gable openings.

The distinctive Dutch Heritage Gable style embodies a classic personality thatcomplements traditional homes. Available in widths of up to 7.5 metres, and a roof pitch of 22 degrees, it comes with a fibre-cement sheet infill in the gable openings.

Technical Details

Maximum Spans

| Maximum Width (S) in mm | |||||

| Wind Speed | Traditional Gable | Dutch Gable | |||

| Attached or Freestanding | Attach End | Attach Side | Freestanding | ||

| 22° | 30° | 22° | 22° | 22° | |

| N1 (W28) | 8400* | 8400* | 7500^ | 7500† | 7500† |

| N2 (W33) | 8400* | 8400* | 7500† | 7500† | 7500† |

| W36N | 8400* | 8400* | 7500† | 7500† | 7500† |

| N3 (W41) | 8400* | 8100* | 7200† | 6900† | 6900† |

| C1 (W41) | 8400* | 8100* | 7200† | 6900† | 6900† |

| N4 (W50) | 6900* | 6600* | 6000† | 6000† | 6000† |

| C2 (W50) | 3900 | 3600 | 3900 | 3900 | 3900 |

| W55C | 3600 | 3300 | 3600 | 3900 | 3900 |

* 12 0 header beam is required where solid infill panels are used ^ One end purlin support required † Two end purlin supports required N = Non-cyclonic wind classification C = Cyclonic wind classification

Note: Attached traditional carports are to have a minimum of two bays. All freestanding traditional carports must have a maximum of three full portal frames.

Attached Connection Details

Traditional Gable

Components

| 1. Attachment Beam | 8. Ridge Knuckle | 15. Footing Knuckle |

| 2. End Portal Frame | 9. Roof Cladding | 16. Ridge Capping |

| 3. Internal Portal Frame | 10. Ridge Connection | 17. Barge Cap |

| 4. Purlins | 11. Roof Cladding | 18. Header Flashing |

| 5. Eaves Purlin | 12. Header Beam | 19. Infill Panel |

| 6. Rafter to Valley Bracket | 13. Footing Connection | 20. Collar Tie Bracket |

| 7. Eaves Knuckle | 14. Footing Plate OR | 21. End Strut |

Dutch Gable

Components

| 1. Attachment Beam | 10. Seated Connection | 19. Footing Plate OR |

| 2. End Frame | 11. Pergola Wall Bracket* | 20. Footing Knuckle |

| 3. Portal Frame | 12. Rafter to Valley Bracket | 21. Ridge Capping |

| 4. Purlins | 13. Eaves Connection | 22. Barge Capping |

| 5. Eaves Purlin | 14. Eaves Knuckle | 23. Hip Flashing |

| 6. Hip Rafter | 15. Ridge Connections | 24. Infil Panel |

| 7. Collar Tie | 16. Ridge Knuckle | 25. Weather Strip |

| 8. End Purlin Support | 17. Roof Cladding | 26. Panel Strip |

| 9. Hip Plate Connection | 18. Footing Connection |

* Or 150mm Modified Suspension Bracket

Freestanding Connection Details

Traditional Gable

Dutch Gable

Components

| 1. Portal Frame | 9. Footing Knuckle | 17. End Wall Column Bracket |

| 2. Corrugated Sheeting | 10. Header Flashing | 18. Hip Plate Connection |

| 3. Purlins | 11. Beam to Wall Bracket | 19. Seated Connection |

| 4. Eaves Knuckle | 12. End Strut | 20. Collar Tie |

| 5. Ridge Knuckle | 13. Header Beam | 21. Dutch Gable Infill Panel |

| 6. Barge Cap | 14. Hip Flashing | 22. Weather Strip |

| 7. Footing Connection | 15. End Frame | 23. Ridge Cap |

| 8. Footing Plate OR | 16. Eaves Purlin Connection | 24. Infill Panel |

Design Options

|  |

| Traditional Gable | Dutch Gable |

Fixing Details

For Non-Cyclonic Areas

Two 12 x 20mm self drilling screws per pan at each support and two 3.2mm sealed aluminium rivets per pan at the back channel. If decking runs parallel to the back channel, secure to channel with rivets at maximum 200mm centres. All screws require neoprene washers.

For Cyclonic Areas

Three 12 x 20mm self drilling screws per pan at each support. For deck spans less than 3600mm, two self drilling screws per pan are to be used on the fascia beam. Three 4.8mm sealed aluminium rivets per pan (or 150mm centres if sheets are parallel) are to be used on the back channel. All screws require neoprene washers.

Structural Sections

|  |

| 120mm Beam | 150mm Beam |

|  |

| Post | Purlin | Back Channel |

Stratco Outback Sunroof

Take control of the weather with the innovative Stratco Outback Sunroof.

Electronically controlled louvres can be opened and closed to your desired position. Let the breeze and sunlight in when the weather is fine. Provide protection when the clouds set in.

Control the weather with the innovative Stratco Outback Sunroof

The versatile Outback Sunroof provides adjustable sun-shade and protection wherever you need it. Combine it with other styles from the Stratco Outback range, or use the Sunroof on its own as an awning, pergola, veranda or patio.

Convenient control

The level of sunlight, shade and weather shielding can be controlled by adjusting the rotating louvre blades with the hand held remote.

The louvres can be rotated to the fully open position to allow for complete overhead sun, or partially open to provide shade and protection while providing adequate ventilation.

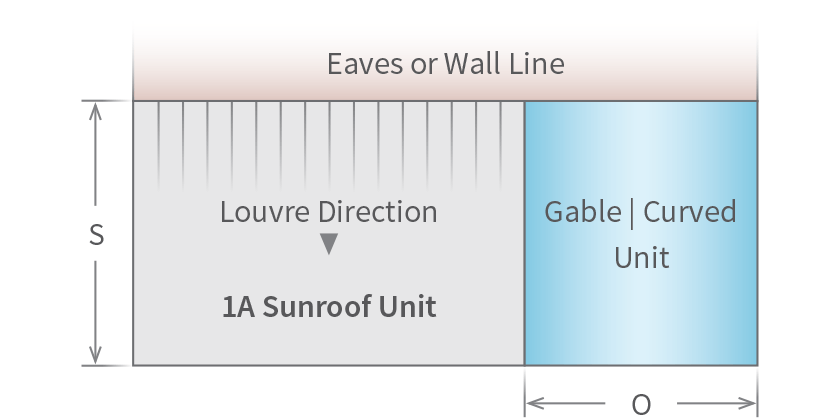

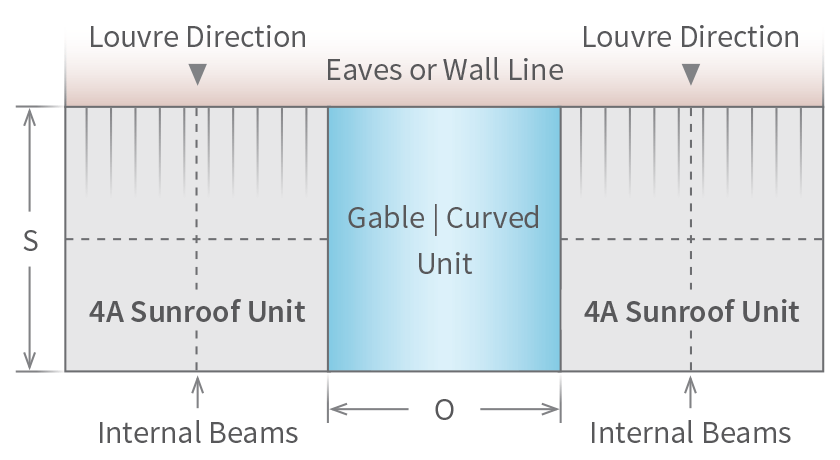

The opening direction of the louvres can be aligned in any one of four directions during installation to optimise light and ventilation control.

Automated intelligence

A rain sensor is fitted to the sunroof as standard, so the louvres automatically close when rain is detected, providing protection from the weather.

When the louvres are in the closed position, they form an interlocking profile providing protection from the rain.

Superior, durable design

The Stratco Outback Sunroof can span up to 3.9 metres thanks to its strong, well engineered blades. The pre-painted steel blades have a unique foam insert that makes them very rigid and helps insulate from any surrounding noise.

Coloured steel, stainless steel, powder-coated aluminium, and plastic materials are used throughout to ensure optimum protection from corrosion.

The entire sunroof system has been durability tested to 20,000 cycles (equivalent to two full cycles per day for more than 25 years).

A powerful 100 watt motor is used to ensure the system operates reliably for life.

It is fitted with a thermal cut-out and adjustable limit stops to prevent damage from misuse.

Quiet and effortless

The Stratco Outback Sunroof’s louvres rotate with a smooth and quiet operating action.

The system’s moving parts use specially designed bushes for whisper quiet performance. Its insulated foam core also dampens operating noise.

The louvres are driven by a powerful 24 volt DC linear actuator for reliable long life operation.

The motor is mounted high above the gutter to ensure protection from rain and pooling water. It is safe to use, and remote controlled.

Complements the entire Stratco Outback Range

The Outback Sunroof louvre blades have been specially designed with a unique, softly ribbed profile so they “look and feel” like part of the Stratco Outback family.

When the louvres are in the closed position, they form an interlocking profile that is both clean-lined and aesthetically similar to Outback Deck.

The Stratco Outback Sunroof can be installed as a stand alone unit, or combined with the Outback Flat Roof, Gable Roof, Curved Roof or Pergola.

Technical Details

Specifications

| Maximum Allowable Lourve Spans (mm) | |||||

| N1 (W28) | N2 (W33) | W36N | N3 (W41) | N4 (W50) | |

| Attached One Side | 3900 | 3900 | 3900 | 3600 | 3000 |

| Corner Attached | 3900 | 3900 | 3600 | 3300 | 2700 |

| Freestanding | 3900 | 3900 | 3900 | 3900 | 3600 |

Values shown are for the outside of the Sunroof perimeter beams.

Note: The above table specifies the maximum allowable louvre spans which are not to be exceeded. For type 4 units with rotated blades the beam spacing for the appropriate closed section must be within these spans for the appropriate attachment style.

| Maximum Spans (S) (mm) – Attached | ||||||

| Type 1A | Type 3A | Type 4A | ||||

| 150 Beam | 150 Beam | 150 Beam | ||||

| Wind Speed | Attached One Side | Corner Attached | Attached One Side | Corner Attached | Attached One Side | Corner Attached |

| N1 (W28) | 3900 | 3900 | 6600 | 6600 | 6600 | 6600 |

| N2 (W33) | 3900 | 3900 | 6600 | 6600 | 6600 | 6600 |

| W36N | 3900 | 3600 | 6600 | 6600 | 6600 | 6600 |

| N3 (W41) | 3600 | 3300 | 6600 | 5400 | 6600* | 6000 |

| N4 (W50) | 3000 | 2700 | 6600* | 4800 | 6600* | 4800 |

* Maximum height to the top of beam is limited to 2700mm.

| Maximum Spans (S) (mm) – Freestanding | |||

| Type 1F | Type 3F | Type 4F | |

| Wind Speed | 150 Beam | 150 Beam | 150 Beam |

| N1 (W28) | 3900 | 6600 | 7200 |

| N2 (W33) | 3900 | 6600 | 7200 |

| W36N | 3900 | 6600 | 7200 |

| N3 (W41) | 3900 | 6600 | 7200 |

| N4 (W50) | 3600 | 6600† | 7200 |

† Columns into concrete only.

Connection Details

Components

| 1. Louvre | 7. Column | 13. Post Cap |

| 2. 150 Outback Beam | 8. Mounting Extrusion | 14. Notched Beam Filler |

| 3. Internal Box Gutter | 9. Motor | 15. Beam to Beam Bracket |

| 4. Link Rod | 10. Motor Bracket | 16. Post Bracket |

| 5. Link Pin | 11. Motor Flashing | 17. Motor Louvre Flashing |

| 6. Mounting Bush | 12. Beam End Cap | 18. Gutter Side Mounting Extrusion |

Louvre Details

| Louvre Profile | Louvre Lapping Details |

|  |

Structural Sections

|  |

| 150mm Beam | Post | Purlin |

Design Considerations

Gable or curved units attached between a Sunroof unit and an existing structure

Gable or curved units which are attached between a Sunroof unit (excluding pergolas) and an existing house, are only be considered attached if the gable or curved unit is attached to the existing house (C) for its full length (L) and the longest side of the combined unit (B) does not exceed twice the gable or curved unit length (L). The Sunroof unit in this case can be considered attached. This style requires all coloumns to be embedded into footings.

Gable or curved units attached to a Sunroof unit on one or both sides

Gable or curved units which are attached on one or both sides to Sunroof units, (excluding pergolas) must be attached to a house for at least 75% of the gable or curved opening length (O) to be considered attached. Sunroof units must be deemed attached as detailed in the Sunroof unit section below for the gable or curved unit to be considered attached.

Gable or curved units are considered attached on both sides if both the Sunroof unit 1 and 2 comply with the attachment rules for Sunroof units as detailed below. Gable or curved units are considered attached on one side if only one Sunroof unit exists and it complies with the attachment rules for Sunroof units as detailed below.

Sunroof units

A verandah, patio or carport is deemed to be freestanding unless it is attached to an existing house (C) for at least 75% of the length of its shortest side (A), and its longest side (B) does not exceed twice the length of its shortest side.

Design Options

When designing an Outback Patio, consideration should be given to both the roof sheet direction, and the orientation of any openings and overhangs involved. These are often determined by appearence and drainage requirements. Some of the normal configurations are shown below. Contact Stratco if assistance is required.

Stratco Outback Pergola

Create an inviting open-air setting that lets light in and improves the appearance of your home.

Add a functional outdoor space to shade and protect recreation areas and delicate plants.

Sun-shade where you need it with the Stratco Outback Pergola

Stratco Outback Pergola

With massive spans of up to eight metres, the Stratco Outback Pergola is available freestanding or attached to your home.

The beams can be left open or fitted with shade cloth for full sun protection. Shade cloth is attached with special clips for a neat finish.

Complete the pergola system with optional profiled beam ends.

Stratco Outback Pergola Shade Blade

Natural filtered light can be created with our innovative Pergola Shade Blade system.

Designed to attach to your pergola as an angled, fixed blade arrangement, Stratco’s Pergola Shade Blade lets the light and breeze in while providing shelter from the sun. The unique blade design has a small gutter to provide protection from light rain.

For added privacy, Pergola Shade Blade can be installed as a side screen. When used as a side screen, the support post centres should be a maximum of 1.2 metres apart.

Technical Details

Specifications

| Maximum rafter spans (mm) | |||

| Wind Speed | Rafter Spacing (B) | Span (S) 120mm Beams | |

| Attached | Freestanding | ||

| W28N to 41N | 600 | 8000 | 8000 |

| 900 | 7400 | 7400 | |

| 1200 | 6800 | 6800 | |

| W50N | 600 | 8000 | 7400 |

| 900 | 6800 | 6200 | |

| 1200 | 5600 | 5600 | |

N = Non-cyclonic wind classification

Connection Details

Components

| 1. Wall Bracket | 6. Connection Sleeve | 11. Post Bracket |

| 2. Purlin/Batten | 7. Connection Bracket | 12. Column |

| 3. 120mm Rafter | 8. Pergola Profiled Beam End | 13. Footing Plate |

| 4. 120mm Fascia Beam | 9. Profiled Beam End Cap | |

| 5. 120mm End Cap | 10. Post Cap |

Stratco Frontier Patio

Carport, Verandah and Patio System

The Stratco Frontier is a simple, well designed, freestanding carport, verandah and patio system. It is economical, and excellent value for money.

The Stratco Frontier is a simple, well designed, freestanding carport, verandah and patio system. It is economical, and excellent value for money.

The Stratco Frontier system is the ideal do it yourself project. Delivered as a complete package with clear, concise instructions, and all components needed to finish the job.

Protect your car with the Stratco Frontier Carport, Verandah and Patio System

Shield your car from the elements or expand your outdoor living and storage possibilities.

Not only will the Stratco Frontier’s heavy duty roof sheeting keep your car cool all year round, but it will give you safe, secure cover from even the largest hail stones and bad weather.

An investment in your home and lifestyle

The durable Stratco Frontier is a lasting investment. The frame is constructed with strong, galvanised c-section beams, and the roofing is manufactured from high quality zinc-aluminium.

Local quality you can count on

The Stratco Frontier carport, verandah and patio system is locally manufactured to strict standards.

Designed to suit local specifications, Stratco can provide a complete set of engineering specifications for quick council approval.

Sizes to suit your lifestyle

The Stratco Frontier is 2.4m high and available in two sizes:

- Single: 3.4m (W) x 5.6m (L) x 2.4m (H)

- Double: 5.35m (W) x 5.6m (L) x 2.4m (H)

Stratco Pavillion

ARCHITECTURAL PROPORTIONS

Experience outdoor living like never before with the unparalleled aesthetic of Pavilion.

The classical architectural proportions of Pavilion created by larger columns and bulkheads, and the distinctive Edge gutter, respond to emerging trends for a more substantial looking structure.

ATTENTION TO DETAIL

With meticulous details such as Aluminium Composite panels (popular in many commercial buildings and architectural projects), integrated LED lighting and concealed fasteners and downpipes, Pavilion adds an element of sophistication, elegance, and glamour to outdoor living.

INSULATED COMPOSITE ROOFING

The smooth ceiling like finish of the insulated composite roofing further enhances the clean, contemporary design and thermal comfort of Pavilion.

A DRAMATIC SENSE OF OPENNESS & SPACE

Engineering capabilities have been optimised to minimise the number of columns required and maximise roof spans, giving Pavilion a dramatic sense of openness and space.

EXTENSIVE COLOUR RANGE

The palette of colours has been inspired by nature and reflects the earthy hues that are seen in the Australian landscape, bridging the gap between urban life and our native environment.

These colours can be mixed and matched to illuminate and reflect the energy of any environment.

SO MUCH MORE THAN JUST AN OUTDOOR LIVING AREA…

ALFRESCO LIVING REDEFINED

Suitable for new builds and retro-fit applications, freestanding or attached, Pavilion will assimilate with and enrich any home environment. This is so much more than just an outdoor living area, this is… alfresco living redefined.

Stratco Cooldek Roofing

Control the climate with the innovative Cooldek insulated roofing panel. Cooldek provides a roof, insulation and ceiling-like finish all-in-one!

It has superior spanning capabilities and outstanding cooling performance.

Control the climate with insulated Stratco Cooldek Roofing

Reduce heat and noise – Save money!

The insulating properties of Stratco Cooldek Roofing reduce heat from above on hot days, significantly increasing comfort levels under the roof.

Cooldek Roofing reduces noise from heavy rain and aids in keeping your home cool, reducing energy costs AND your carbon footprint.

Stratco Cooldek Roofing features a polystyrene core that is permanently bonded to a smooth, easy to clean, coloured steel underside, and a profiled, coloured steel topside.

Finish and colour options to suit your home

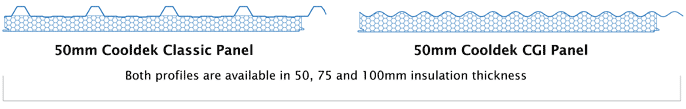

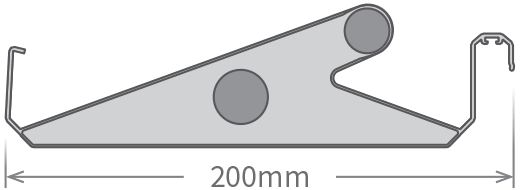

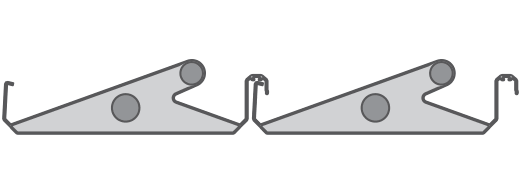

Choose from either the Cooldek Classic or the Cooldek CGI roofingprofiles.

For the underside, there is a choice of smooth or one of two ribbed profile finishes. These are available in white or a choice of high gloss colours.

The topside colour choices include a wide range of colours to integrate your carport, pergola, verandah or patio into existing colour schemes.

There are three insulation thicknesses to choose from:

- 50mm thick panels with an insulation rating (R value) of up to 1.6

- 75mm thick panels with an insulation rating of up to 2.2

- 100mm panels with an insulation rating of up to 2.8

Strong, sleek and easy to install

Exceptional strength allows Stratco Cooldek Roofing to span up to an impressive 7 metres.

Large spans reduce the number of beams and framework, creating an uncluttered, ceiling-like appearance.

Simple to install, Stratco Cooldek roofing has an inbuilt rebate to conceal electrical wiring for fans and light fittings.

Cooldek Technical Information Profile

Design Considerations

The minimum recommended roof pitch for “flat” verandahs shall be 2° (1 in 30) for Cooldek Classic panels and 3° (1 in 20) for Cooldek CGI panels. The maximum roof pitch for “flat” verandahs shall be 5° (1 in 12). Care must be taken to ensure the minimum roof pitch is maintained to avoid ponding of rainwater.The roof is designed to withstand actions incidental to maintenance, roofs are not to be used for floor type activities.The design contained within these span tables relate to wind classifications N1, N2, N3, and N4 applicable to Regions A and B. Stratco does not accept liability for any loss or damage suffered as a result of any errors in the interpretation or application of these span tables.| Material Specifications | ||||

| Material Properties | Cooldek Classic | Cooldek CGI | ||

| Base Metal Thickness / Material Grade | Top Skin | 0.42mm / G550 | 0.42mm / G550 | |

| Bottom Skin | 0.50mm / G300 | 0.50mm / G300 | ||

| Mass (kg / linear metre) | 50mm Panel | 9.5 | 9.6 | |

| 75mm Panel | 9.8 | 9.9 | ||

| 100mm Panel | 10.1 | 10.2 | ||

| Width Coverage (mm) | 1000 | 1000 | ||

| Minimum Roof Pitch | 2° | 3° | ||

| Core | Material | SL Grade EPS (expanded polystyrene) | ||

| Thermal Conductivity | 0.037 W/mK (0°C mean temperature) | |||

Compliance

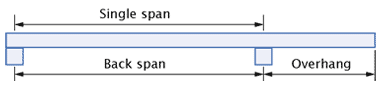

The Wind Capacity Tables are based on testing in accordance with AS1562.1-1992 and AS4040.0, 1 & 2-1992. Span tables have been developed by determining wind pressures in accordance with AS4055-2012 for domestic applications. Capacity tables are in limit state format.Spans

The spans given in the ‘Single Spans’ table are determined for wind speeds for non-cyclonic areas. Indicated spans are suitable for ‘flat’ roof patios. Open freestanding unit spans can be taken from open three sides unless a wall, eaves or boundary exists within 500mm of two or more sides.For Cooldek roofing in attached or freestanding domestic gable patio application, sheet spans shall not exceed those given for one or no open sides. Alternatively the ‘Wind Capacities’ table may be used to determine allowable single spans for any application.Spans specified for units with three sides open are suitable for units considered ’empty under’ and not exceeding three metres in height (from ground or deck level). For units in which goods or materials stored under the roof are expected to block greater than 50% of any open side exposed to the wind spans are to be taken from open two sides.For units with two open sides, spans are based on Cp,n=-1.0 while for units with only one or no open sides, Cp,n=-1.2. In all cases, relevant consideration has been given to local pressure. Note: The ‘Wind Capacities’ table provides allowable wind capacities for Cooldek in single span application for serviceability and strength limit states. The pressures given may be used by a suitably qualified engineer for any single span application ensuring appropriate fixing details are applied.Single Spans – Domestic Patio Application| Single Spans – Domestic Patio Application (mm) | |||||||||

| Open Sides | Panel Thickness (mm) | COOLDEK CLASSIC | COOLDEK CGI | ||||||

| N1 (W28) | N2 (W33) | N3 (W41) | N4 (W50) | N1 (W28) | N2 (W33) | N3 (W41) | N4 (W50) | ||

| Three | 50 | 5400 | 5400 | 5400 | 4200 (3900) | 5400 | 5400 | 5100 | 3900 |

| 75 | 6600 | 6600 | 6000 | 4800 (3900) | 6600 | 6600 | 6000 | 4800 (3900) | |

| 100 | 7200 | 7200 | 6600 | 6000 | 7200 | 7200 | 6900 | 6000 | |

| Two | 50 | 5400 | 5400 | 3900 | 3300 (2100) | 5400 | 5100 | 3600 | 3000 |

| 75 | 6600 | 5500 | 4800 (4400) | 3900 (2100) | 6600 | 5700 | 4800 | 3900 (3000) | |

| 100 | 7200 | 6300 | 5400 (5400) | 4100 (n/a) | 7200 | 6600 | 5400 | 4100 (3500) | |

| One/None or Gable Patio | 50 | 5400 | 4500 | 3300 | 3000 (n/a) | 5400 | 4500 | 3300 | 3000 (2000) |

| 75 | 6000 | 4800 | 3900 (3300) | 3300 (n/a) | 6300 | 5100 | 3900 | 3300 (2100) | |

| 100 | 6900 | 5400 | 4200 (3100) | 3600 (n/a) | 7200 | 5700 | 4200 | 3600 (2400) | |

Maximum allowable 900mm deck overhang for 50 and 75mm panels and 1200mm for 100mm panels, except in wind classification N4 in which maximum allowable shall be 900mm. The cladding back span shall be no less than 1.5 times the deck overhang. If values are shown in brackets they represent the maximum allowable span if an overhang is used. For a side to be considered open, the full length of the side must be open.

Single Span Wind Capacities (kPa)| Single Span Wind Capacities (kPa) | ||||||||||||

| Profile | Panel Thickness (mm) | Limit State | Span (mm) | |||||||||

| 1800 | 2400 | 3000 | 3600 | 4200 | 4800 | 5400 | 6000 | 6600 | 7200 | |||

| Classic | 50 | Serviceability | 3.80 | 2.69 | 2.06 | 1.66 | 1.38 | 1.18 | 1.02 | – | – | – |

| Strength | 6.70 | 4.50 | 3.30 | 2.56 | 2.07 | 1.72 | 1.46 | – | – | – | ||

| 75 | Serviceability | – | 4.86 | 3.43 | 2.58 | 2.02 | 1.64 | 1.37 | 1.16 | 1.00 | – | |

| Strength | – | 5.11 | 3.63 | 2.75 | 2.17 | 1.77 | 1.48 | 1.26 | 1.08 | – | ||

| 100 | Serviceability | – | – | 3.51 | 2.78 | 2.27 | 1.91 | 1.65 | 1.44 | 1.27 | 1.14 | |

| Strength | – | – | 4.58 | 3.47 | 2.74 | 2.24 | 1.87 | 1.59 | 1.38 | 1.21 | ||

| CGI | 50 | Serviceability | 3.72 | 2.62 | 1.99 | 1.60 | 1.32 | 1.13 | 0.97 | – | – | – |

| Strength | 6.78 | 4.47 | 3.24 | 2.49 | 1.99 | 1.64 | 1.38 | – | – | – | ||

| 75 | Serviceability | – | 3.81 | 2.86 | 2.27 | 1.86 | 1.57 | 1.35 | 1.18 | 1.04 | – | |

| Strength | – | 5.84 | 4.15 | 3.14 | 2.48 | 2.02 | 1.69 | 1.44 | 1.24 | – | ||

| 100 | Serviceability | – | – | 3.74 | 2.89 | 2.33 | 1.93 | 1.63 | 1.41 | 1.23 | 1.09 | |

| Strength | – | – | 4.20 | 3.30 | 2.69 | 2.25 | 1.92 | 1.67 | 1.47 | 1.31 | ||

The values in all the above tables are for use with steel supports with a minimum thickness of 1.0mm BMT, G550, or timber supports with fixing details as specified below.

Walking on Cooldek

When walking on Cooldek roofing, it is recommended you walk over the support beam to avoid damage. Wear flat, rubber soled shoes and walk flat footed in the sheet pans for Classic, and with your weight spread over as many crests as possible for CGI. For carport and verandah applications, away from supports, crawl boards should be used to avoid damage during installation and maintenance.

Maintenance

The performance of Cooldek over time depends on its correct application and maintenance. Maintenance should be performed as often as is required to remove dirt, salt and pollutants.

Where used in severely corrosive environments, cleaning should be performed more often.

It is important that screws have the same life expectancy as the cladding you have specified.

Packs of Cooldek should always be kept dry and stored above ground level while on site. If the sheets have become wet, they should be separated, wiped and placed in the open to dry.

Refer to Stratco “Selection, Use and Maintenance” brochure, for more detailed information about the correct use and maintenance of this product.

Ambient Outdoor Blinds

Adelaide Hills Outdoor Blinds: Mt Barker Steel is your Stratco Ambient Adelaide Hills Outdoor Blinds Dealer. Ambient Blinds are so simple and quick to open and close, anyone can do it! To get an obligation free quotation for Adelaide Hills Outdoor Blinds please contact us today!

ULTIMATE SCREENING SOLUTION

Specially designed for alfresco entertaining areas such as pergolas, verandahs and balconies, Stratco Ambient Blinds offer privacy and protection from the sun, wind, rain and insects all year round. Also ideal for home and office windows, Ambient Blinds serve as a sleek, secure and durable alternative to traditional awnings and roller shutters. Your custom designed system can be made in widths of up to 5 metres or drops of up to 4 metres, offering you an external solution to fit almost any area.

CLEVER ENGINEERING

Cleverly constructed with hidden interlocking parts, the Ambient Blinds system features self-aligning side channels enabling installation in ‘out of square’ areas, unlike many outdoor shade blinds. Suitable for both residential and commercial applications, options include an enclosed box, a range of custom colours and various controls to suit your individual requirements.

PROTECTION AND PRIVACY

Strong and durable, the Ambient Blinds system offers protection from the sun, UV rays and inclement weather. In addition, the secure, custom-made fit can provide an insect-free environment in which to rest and relax. Suited for a wide range of conditions, it is the perfect solution for any outdoor residential or commercial application. The Ambient Blinds system will ensure you receive your desired level of privacy and comfort. Various external fabric choices are available, including popular screen mesh fabrics to control the amount of visibility, or total black-out solutions.

STYLISH DESIGN

The simple yet stylish design improves the presentation of any home or office, defining outdoor areas and extending your entertaining space from your kitchen or lounge. It also provides a sleek external finish to any window. Functional, compact and easy to install, the Ambient Blinds system is made with only the best quality external grade extrusions.

COLOUR RANGE

The Ambient Blinds system is readily available in a choice of four standard frame colours – Alpine, Sand Dune, Desert or Deep Space, with a choice of 19 fabric colours and 3 openness factors. With mill extrusions available, we can also custom match the frame to your existing outdoor décor. All Ambient Blinds frame colours are powder-coated to an exceptional exterior grade quality, providing a superior, long lasting solution to any outdoor area.